PRODUCT

Safety/Support/Service

CONTACT

HOT LINE:

+86-13503720779

+86-18003728887

18837284400

ayptfmachine@163.com

TEL:+86-0372-3870592

ADDRESS:No.1 Road, Equipment Demonstration Park, High tech Zone, Anyang City, Henan Province

CK8463

Focus on designing and manufacturing CNC machine tools

- TEL: +86-13503720779

地址:No.1 Road, Equipment Demonstration Park, High tech Zone, Anyang City, Henan Province

Product Description

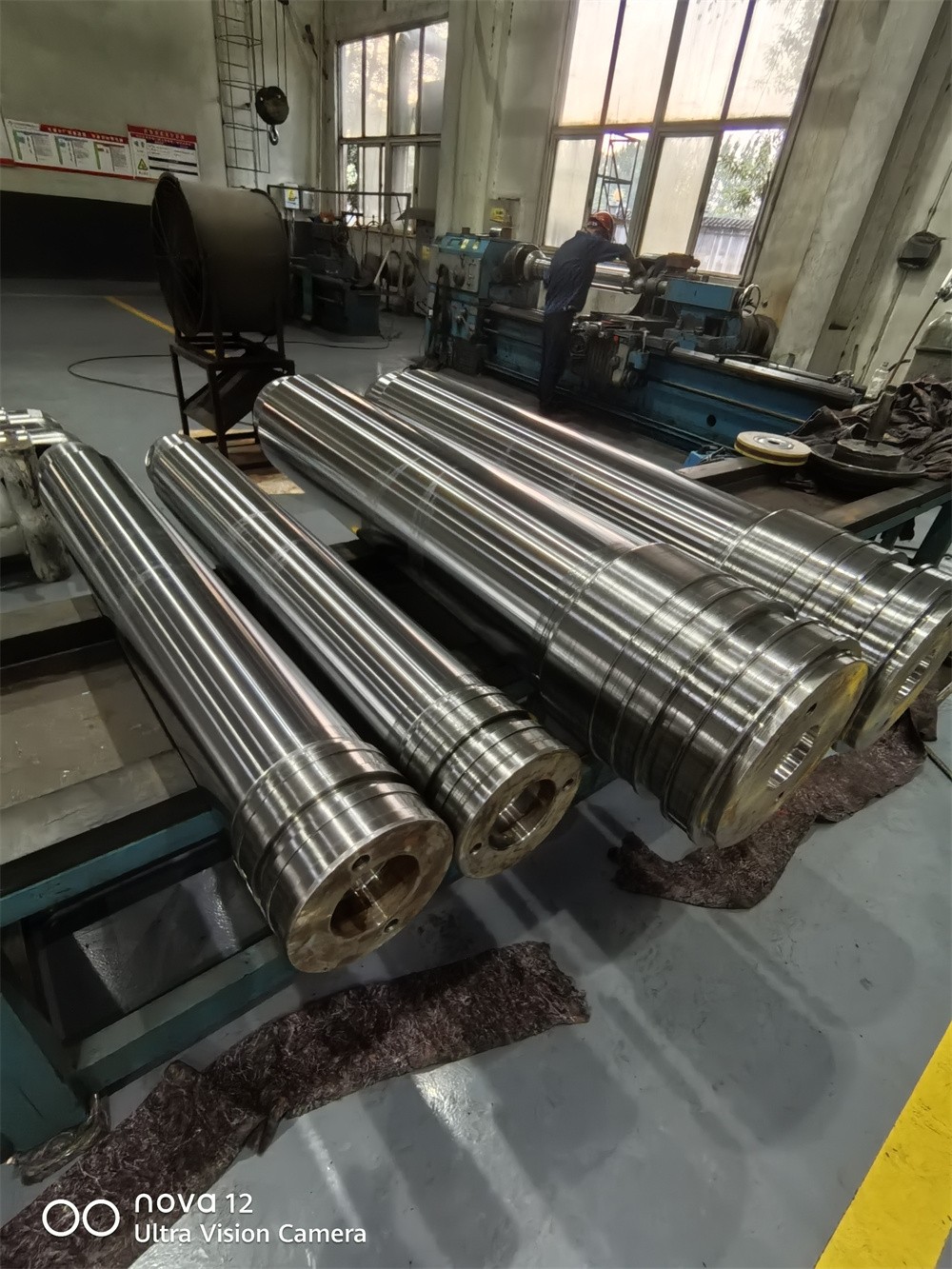

The CK84 series high-precision CNC rolling mill lathe is a high-precision, high rigidity, four rail CNC rolling mill lathe independently developed by our company in combination with the market situation. It is mainly suitable for processing various types of rollers, and can also be used for batch processing of internal and external circles, conical surfaces, end faces, and threads of various workpieces such as shafts and disks. High efficiency, simple operation, safe and reliable. Widely used in mechanical processing in industries such as steel, coal chemical, maintenance, automotive, petroleum, and military.

The standard configuration of the system is Siemens CNC system from Germany;

The feed system is driven by high-precision imported ball screw direct servo motor, and the guide rail adopts rectangular hard rail or heavy-duty linear guide rail, which is supported by imported ball screw bearings and has high rigidity, high precision, and fast response, suitable for high-speed and high-precision cutting; The surface of the hard rail is treated with laser heat treatment to increase its hardness, wear resistance, and extend its service life;

The tailstock adopts a built-in rotating top to improve its rigidity and machining accuracy of parts; The electrical components mainly adopt imported brand products, and the electrical box is equipped with air conditioning as standard;

CK84系列技术参数 SPECIFICATIONS

Item | unit | CK8450 | CK8465 | CK8485 | CK8465 | CK8485 | CK84100 | CK84100 | CK84125 | CK84160 | |

Capacities | Swing over bed | mm | φ500 | Φ650 | Φ850 | Φ650 | Φ850 | Φ1000 | Φ1000 | Φ1250 | Φ1600 |

Max turning dia | mm | φ500 | Φ650 | Φ850 | Φ650 | Φ850 | Φ1000 | Φ1000 | Φ1250 | Φ1600 | |

Max workpiece length | mm | 2500-3000 | 3500-5000 | 5000/6000/8000 | |||||||

Max turning length | mm | 2300-3000 | 3000-4800 | 4800/5800/7800 | |||||||

Span of guideway | mm | 850/900 | 1100 | 1450 | |||||||

Max weight of workpiece | Kg | 3600/4000 | 8000 | 20000 | |||||||

Feed motion | X-axis travel | mm | 330 | 450 | 450 | ||||||

Z-axis travel | mm | 2400/3000 | 3200/4900 | 4900/5900/7900 | |||||||

X/Z-axis rapid traverse | mm/min | 3000/6000 | 3000/6000 | 3000/6000 | |||||||

Min feed increment of X/Z-axis | mm | 0.001 | 0.001 | 0.001 | |||||||

Spindle | Spindle speed(stepless) | rpm | 10-500 | 8-350 | 5-200 | ||||||

Spindle nose | C2-11 | A2-15 | A2-15 | ||||||||

Spindle bore(dia.) | mm | φ100 | φ130 | Φ96 | |||||||

Cone hole of spindle | 公制120 Metric 120 | 公制140 Metric 140 | |||||||||

Taper of spindle center | MT-5 | MT-6 | MT-6 | ||||||||

Spindle motor | KW | AC22(30) | AC30/AC45 | AC75 | |||||||

Manual 4-jaw chuck | mm | 手动四爪φ500mm -φ560mm | 手动四爪φ630mm -φ800mm | 手动四爪φ800mm -φ1250mm | |||||||

Turret

| Number of stations | 立式四工位 vertical 4-position | |||||||||

Turret siz | mm | 280×280 | 300×300 | 380×380 | |||||||

Tool shank size | mm | 40×40 | 40×40 | 50×50 | |||||||

Tailstock | Diameter of tailstock quil | mm | Φ200 | Φ220 | Φ300 | ||||||

Travel of tailstock quill | mm | 310 | 330 | 310 | |||||||

Taper hole of tailstock quill | MT-5 | MT-6 | MT-6 | ||||||||

Others | 执行标准:JB/T8324.1-96简式数控卧式车床精度、 JB/T8324.2-96简式数控卧式车床技术条件 | ||||||||||

工件精度:IT6~IT7 | |||||||||||

面粗糙度:Ra0.8 | |||||||||||