PRODUCT

Safety/Support/Service

CONTACT

HOT LINE:

+86-13503720779

+86-18003728887

18837284400

ayptfmachine@163.com

TEL:+86-0372-3870592

ADDRESS:No.1 Road, Equipment Demonstration Park, High tech Zone, Anyang City, Henan Province

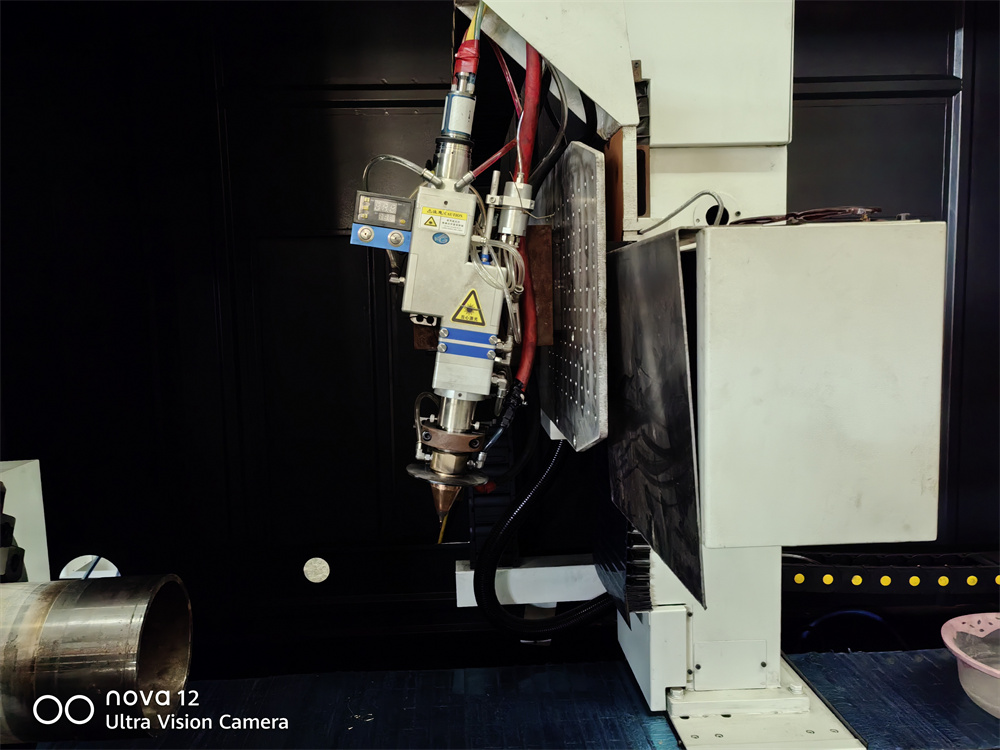

Laser cladding equipment

Focus on designing and manufacturing CNC machine tools

- TEL: +86-13503720779

地址:No.1 Road, Equipment Demonstration Park, High tech Zone, Anyang City, Henan Province

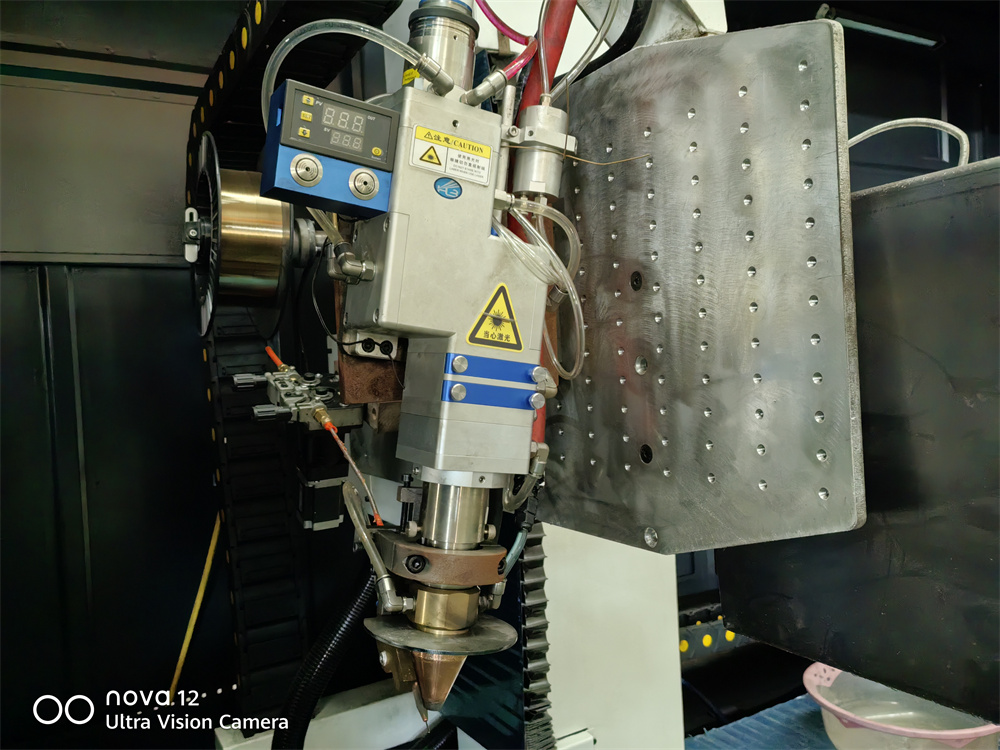

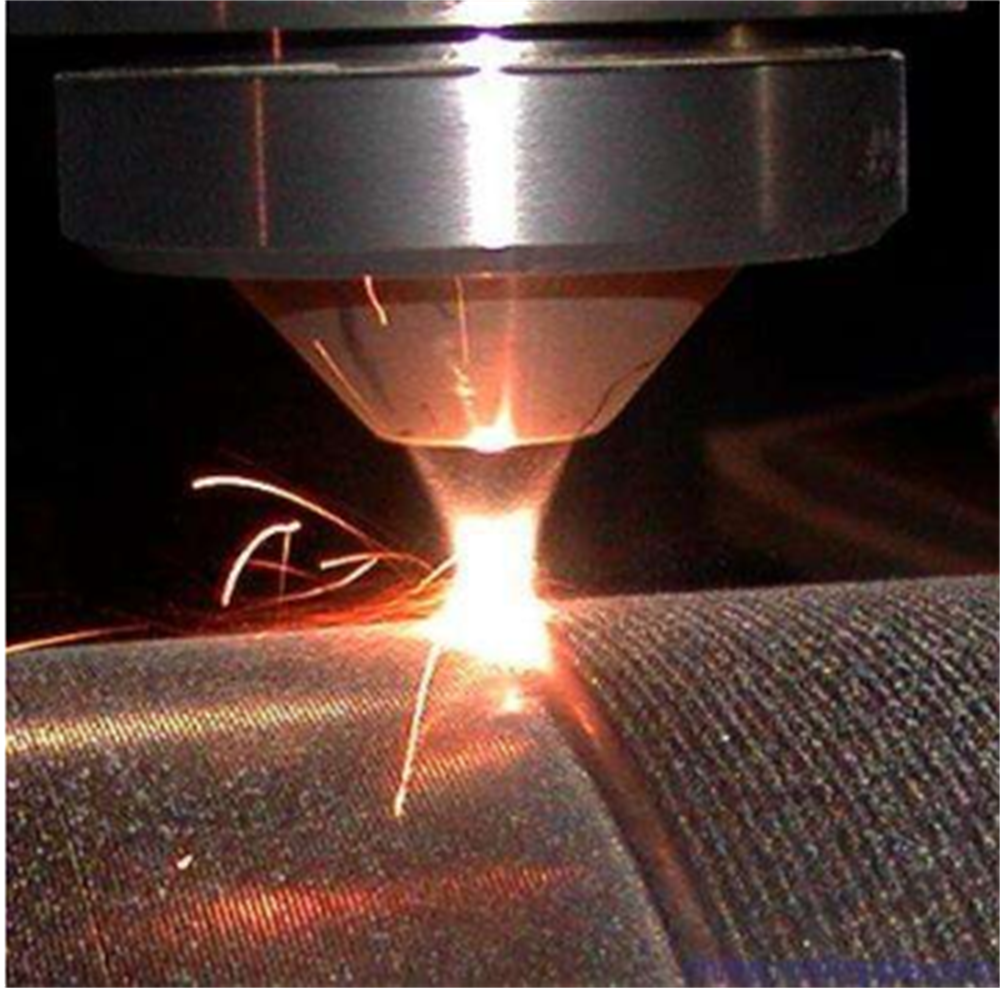

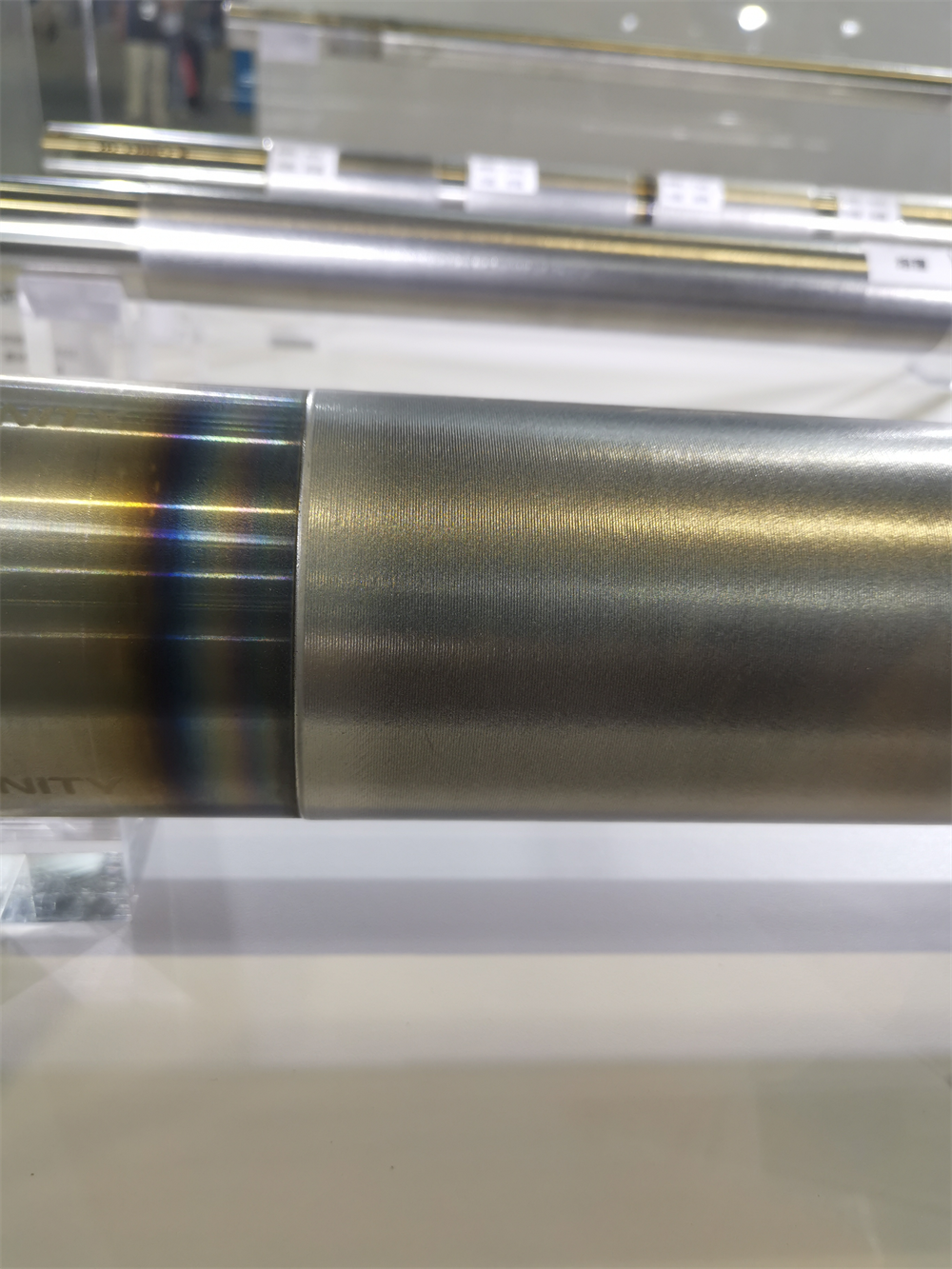

Laser cladding is a process that uses an automatic powder feeding system and an automatic wire feeding system to feed powder or wire into a laser melt pool, so that the alloy powder or wire can achieve metallurgical bonding with the surface layer of the substrate, forming a metal coating layer. It can effectively improve the specific properties of the substrate's wear resistance, corrosion resistance, and strength. The energy density of laser cladding heat source is high, the heat affected zone generated in the part is small, and it is not easy to deform. It is suitable for repairing or strengthening high-precision parts and parts with strict deformation requirements.

The laser cladding layer has a dense structure, low porosity, and no defects. The fusion layer achieves metallurgical bonding with the substrate, with high strength and good toughness, suitable for surface modification and repair of heavy-duty parts. Laser cladding can select materials with various properties according to different working conditions and environments.

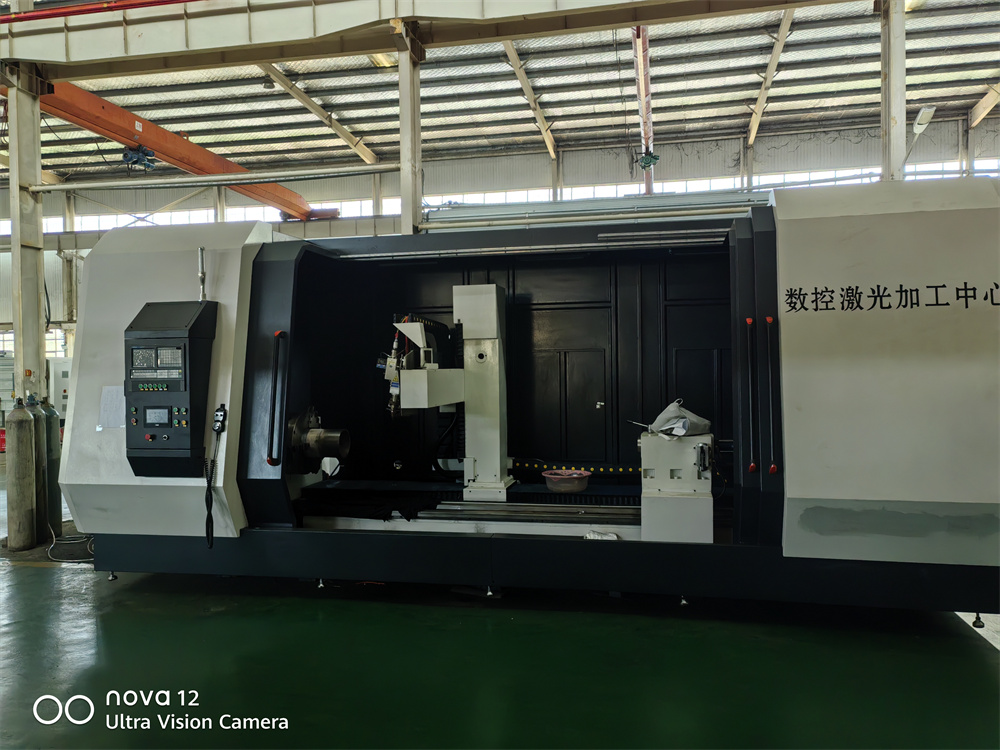

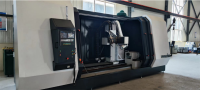

The CKJR series CNC cladding machine is a fully functional CNC cladding lathe with semi closed loop control function developed by the company based on the new development trend of CNC laser heat treatment technology in the market. This machine tool has a wide range of applications, flexible operation, and is suitable for cladding processing of various complex shaped shaft, sleeve, and disc parts, such as outer cylindrical surfaces, conical surfaces, circular arc surfaces, end faces, chamfers, etc. It is particularly suitable for multi variety, small to medium batch wheel processing, with strong process adaptability, high efficiency, good product consistency, and can reduce the requirement for workers' technical proficiency. Easy to program and operate, it is an ideal medium-sized CNC machining equipment.

SPECIFICATIONS:

CAPACITY | ITEM | UNIT | |

SWING OVER BED | mm | 900 | |

DISTANCE BETWEEN CENTERS | mm | 3000 | |

MAX. CUTTING LENGTH | mm | 3000 | |

GUIDEWAY WIDTH | mm | 880 | |

SPINDLE | RUNOUT OF SPINDLE | mm | 0.03 |

SPINDLE SPEED | rpm | 0.05-60 | |

TRAVEL | X AXIS TRAVEL | mm | 500 |

Y AXIS TRAL | mm | 500 | |

Z AXIS TRAVEL | mm | 3000 +100 | |

X/Z FEEDING SPEED | M/min | 5 | |

HYDRALIC TAILSTOCK | DIA. OF TAILSTOCK QUILL | mm | 100 |

TRAVEL OF TAILSTOCK QUILL | mm | 250 | |

TAPER HOLE OF QUILL | MORSE 5 | ||

MAX.LOAD OF CENTER | kg | 3000 | |

MOTION MODE OF TAILSTOCK | ELECTRIC MODE | ||

POWER SYSTEM | MAIN SERVO MOTOR | kw | 3.3 |

MAIN MOTOR SPEED | rpm | 2000 | |

X AXIS MOTOR TORQUE | N.m | 7 | |

Y AXIS MOTOR TORQUE | N.m | 7(加装精密减速机) | |

Z AXIS MOTOR TORQUE | N.m | 10(加装精密减速机) | |

OTHERS | THREE JAW CHUCK | mm | 630 |

REPAIR TOOLS | set | 1 | |

CENTER HEIGHT | mm | 500 | |

MACHINE WEIGHT | kg | 5500 |